Carbeon-HPSHigh Precision Structures

Carbeon-HPS is specifically tailored for high precision systems where co-efficient of thermal expansion of a component can highly influence the output of a system. Carbeon-HPS combines fiber architecture and design expertise to obtain near zero co-efficient of thermal expansion along with significant weight reduction.

Material properties

| Property | Density | CTE (in plane) | Young’s Modulus | Thermal Conductivity | Open Porosity | Outgassing (TML) |

| Units | g/cm3 | (10-6) K-1 | GPa | W/mK | % | % |

| Value | 1.9-2.1 | 0 to 1(1) | 60-250 | 15-150 | 1-2 | 0.01 |

(1) -40 °C to +100 °C (in plane)

NOTE: This technical data sheet reflects the general characteristics of the material which can be tailored to specific needs. Actual properties and combinations may vary according to the environment where the products are to be used.

Material properties

| Property | Units | Value |

| Density | g/cm3 | 1.9-2.1 |

| CTE (in plane) | (10-6) K-1 | 0 to 1(1) |

| Young’s Modulus | GPa | 60-250 |

| Thermal Conductivity | W/mK | 15-150 |

| Open Porosity | % | 1-2 |

| Outgassing (TML) | % | 0.01 |

(1) -40 °C to +100 °C (in plane)

NOTE: This technical data sheet reflects the general characteristics of the material which can be tailored to specific needs. Actual properties and combinations may vary according to the environment where the products are to be used.

Advantages

- Near zero coefficient of thermal expansion for highly accurate mechanism

- Lightweight structures due to low material density (1.9 g/cm3 ) and thin walled geometries (t ≥ 0.15mm) for fast moving components

- Environmentally stable. No swelling or detectable outgassing in vacuum allows the use of our composite near optics

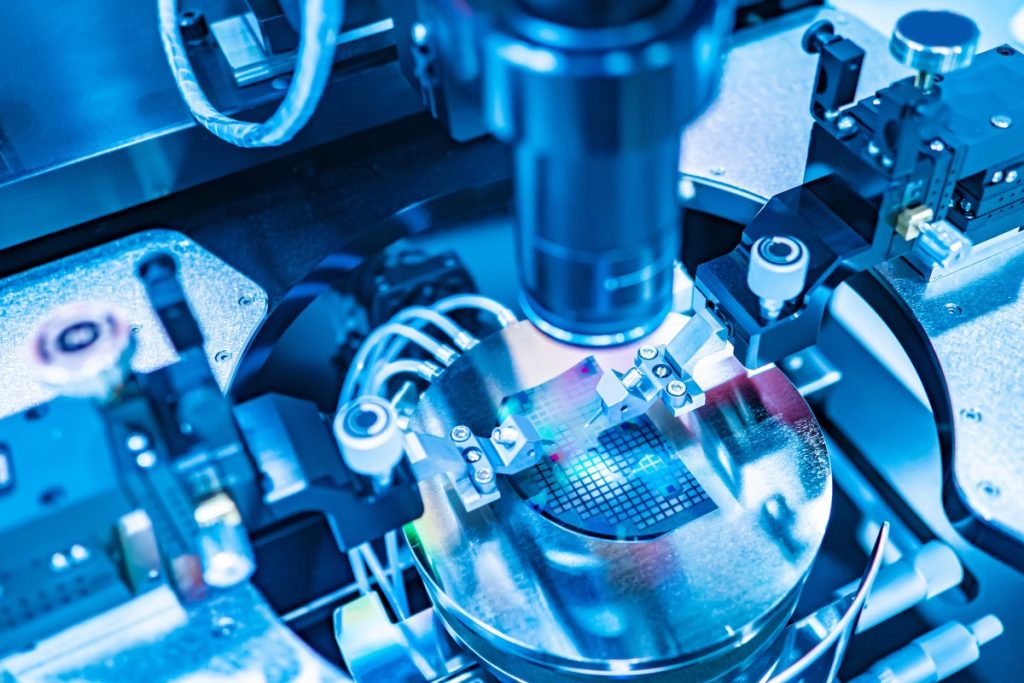

Application Domain

- Lithography

- Laser

- Calibration

- Opto-mechanical

- Medical equipments

- Analysing equipments