About us

Overview

Arceon was founded in 2018 Arceon with the vision to empower revolutionary technology advances by developing materials (Ceramic Matrix Composites – CMCs) with unique properties such as extreme heat resistance, superior durability and reduced corrosion levels, among others.

Offering a wide range of customized and comprehensive solutions, enhancements and innovations on existing as well as future challenges, the company is currently active on the aerospace, aviation, and industrial equipment global markets.

Comprised of a team of talented professionals and highly-equipped scientists, Arceon has demonstrated strong potential for rapid expansion to highly promising and vital industries due to the products’ extensive applications as well as continuous and multi-dimensional business growth.

Our goal is to become a trend-setter in the field of novel material by bridging the gap between research and industry, while remain loyal to our key principles of: Innovation, Sustainability and Evolution.

How We Work

We support our clients to respond to future developments through cutting edge Research and Development projects leading to novel materials and manufacturing techniques. This is achieved by foreseeing their sophisticated needs while providing innovative solutions and enhancements. Materials can be developed to provide customized solutions depending on the project’s specific requirements.

Team

Rahul started his entrepreneurial journey in early 2017. He has always been passionate about innovations which pushes human race forward and supports sustainable development. He has completed his master’s in Aerospace Structures and Materials from TU Delft, Netherlands. His passion towards innovation and experience with composites led to the formation of Arceon. His role focuses on accelerating the overall growth of the company.

Rahul

Shirke

CEO

Bernhard Heidenreich has over 25 years of experience as a researcher and project manager at Deutsches Zentrum fur Luft-und Raumfahrt. He has over 80 publications on CMCs . His immense knowledge and valuable experience assist ARCEON in overcoming technical barriers and ensures successful execution of projects.

Bernhard Heidenreich

Co-founder & Technical Lead

Rahul comes with an experience of 3.5 years in product design and development in the automotive industry. With his proficiency in new product development and project management, he is advancing Arceon to achieve its goal of bridging the gap between scientific research and industrialization. He has a master’s in Mechanical Engineering from TU Delft, Netherlands. His pragmatic approach to finding novel design solutions helps our customers to achieve an optimal design made of ArCMC material.

Rahul

Sharma

Co-founder & COO

Yestin van Haaren joined Arceon as a mechanical engineering intern. He did his Master’s at the Aerospace Engineering faculty of TU Delft, where he followed a track focused on aerospace structures and materials. He has always been interested in space flight and engineering and recently in the structural side in particular. He has also taken a real interest in carbon fiber composite materials and all the possibilities they provide.

He is enthusiastic about his new role at Arceon, which is working on the space related manufacturing projects at Arceon.

Yestin van Haaren

Project Engineer Space

After completing her bachelor’s education in Materials Engineering, she continued her master’s in the Ceramic Engineering at Istanbul Technical University. She has previously gained experience in vacuum brazing methods, the development of electromagnetically permeable composite radome wall structures, and gaining knowledge about many composite manufacturing methods. Using these experiences, to develop materials used in space is one of her biggest dreams. She focusses on vacuum brazing joining methods of CMC to supper alloys used in nozzle structures as well as fundamental materials research.

Ebrar Ozbek Ekiz

Team Lead Process and Materials

Alberto is currently pursuing a master’s degree in Aerospace Engineering at TU Delft in structures and materials, with a strong interest in composite materials and their applications. He is passionate about solving complex engineering problems and contributing to the advancement of aerospace technology, and excited for the opportunity to learn more about these materials and develop new skills at Arceon

Alberto Bombace

Internship: Manufacturing Process Modelling

I am a third-year aeronautical engineering student from Inholland University of applied science. My motivation for pursuing the study comes from my passion for space. And wanted to pursue a career in this field. During the study I learned all about aeronautical engineering. And this is where I encountered composites. For the project of building a subscale airplane, we needed to manufacture a composite skin for the nose cone. This made me eager for more. With Arceon I would like to enhance my knowledge of composites and help the company to improve.

Paul Duijverman

Aeronautical Engineering Intern

I am a third year Aerospace Engineering student at Delft University of Technology. My passion for aviation and space has driven my desire for knowledge in the field. While working for AQUILO rocket team as an electronics engineer and further as Head of electronics, being around the rocket all the time, I developed a curiosity for material science. Besides, I also had the opportunity to start working with composite materials in manufacturing the rockets. Carrying out manufacturing projects, Arceon gave me the opportunity to follow this curiosity and expand my knowledge into fiber based CMCs and composite materials in general.

Paul Ionut Huciu

Composites Manufacturing Engineer

I am a third-year aeronautical engineering student at InHolland University with a growing interest in composite materials. My interest in composites began throughout the course of my studies, which lead me to pursuing in this field of study by working at Arceon. Arceon provided me with the opportunity to learn more about composites by optimizing their manufacturing method of short fiber composites, and I am excited to further develop my knowledge in this field of study. I apply my knowledge and experience in the Tryden-Nova Electric Racing student team as a drive train engineer and also apply the knowledge I gained from my student team into my task at Arceon. This relationship helps me grow as an engineer and pursue my passion in racing and composite materials

Willam

Hou

Aeronautical Engineering Intern

Advisors

Dimitrios Zarouchas is an assistant professor at TU Delft Aerospace Structures and Materials department. He has over 10 years of research experience in the field of composites. His research focuses on the damage tolerance design of polymer composites, adhesively bonded metallic and composite structures, experimental mechanics and health and condition monitoring systems. Dimitrios assists ARCEON with the technical developments.

Dimitrios Zarouchas

Technical Advisor

Duke’s entrepreneurial journey started 1984 when he founded his own company. The business grew globally and was eventually sold to a U.S. company in 1999. Since then, Duke has started a couple of new ventures, invested in others, and passed on his knowledge to more entrepreneurs than he can remember. He assists ARCEON with business development strategies and mentorship.

Duke

Urbanik

Business Strategy Mentor

Andrea is a space, defense, and tech business leader and entrepreneur, equally comfortable and experienced in leading commercial and operational organizations of innovative and growth-oriented technology, engineering & service companies. He is supporting Arceon with investment and scale-up strategy.

Andrea Bennetti

Scale-up Mentor

Projects

T-Prime

The project focuses on demonstrating the capabilities of its Carbeon-UHT ceramic composite by significantly reducing the nozzle weight and sustaining the hypersonic pressure and thermal loads. A graphite nozzle is replaced with a relatively thin wall thickness Carbeon-UHT material. The weight reduction at the tail of the rocket directly impacts the overall efficiency of the rocket. Carbeon-UHT nozzle not only has to withstand the thermal and pressure loads but also need to resist the abrasion caused by the propellant particles. This project truly defines the character and quality of the material in harsh environments.

SPEAR

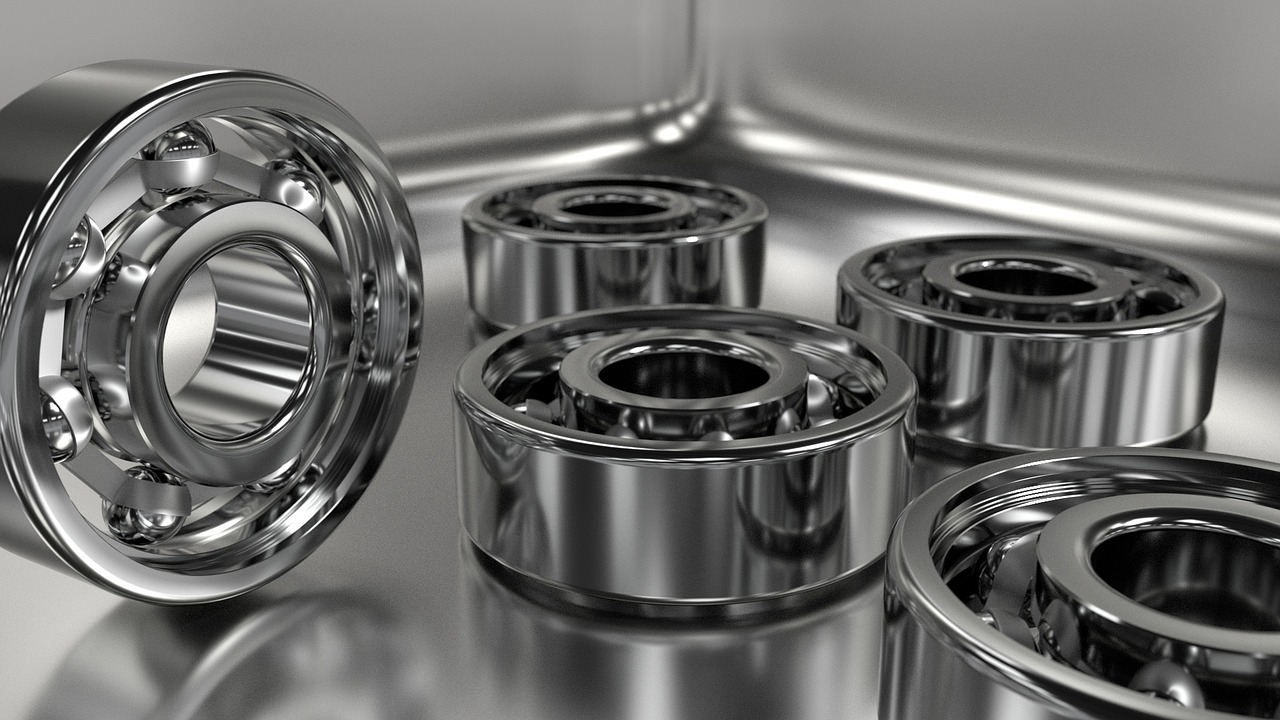

The SPEAR project focuses on developing high performance bearings for a wide range of industries such as aviation and machinery equipment. Demonstrating a high load carrying component with extremely low wear, self-lubricating, lightweight and ultra-high temperature stability, it is an amalgamation of design architecture, manufacturing, and assembly expertise. One of the challenges we tackled is designing a bearing which compliments the co-efficient of thermal expansion of its metal partner. The output of SPEAR will result in enhanced tribology competence and life-cycle of a system.

ATLAS

The development of next generation space exploration propulsion systems requires high temperature materials able to guarantee low density, high strength, oxidation resistance, good creep properties, long-term vacuum and irradiation stability. To achieve this goal Arceon with its ceramic matrix composite knowledge, will work together with Politechnico Di Milano, University of Derby - UK, TISICS Limited, Ques Tek Europe AB, DLR, Yousciencbc Ltd. and Dawn Aerospace.

Lunar Zebro

Lunar Zebro is the world's smallest and lightest rover yet, built by TU Delft students from the faculty of Electrical Engineering, Mathematics and Computer Science (EEMCS), to be sent to the Moon. ARCEON is engineering and manufacturing advance ceramic matrix composite (CMC) parts for this mission, to enhance the vehicle’s design and performance. The mission will explore the lunar surface and carry out on-ground imaging. Once the Rover has completed its primary mission it will cover as much distance as possible to test the power and durability of the system. This project introduces ground-breaking innovation in every detail and allows Arceon to prove the credibility of its novel material and unleash its full potential.

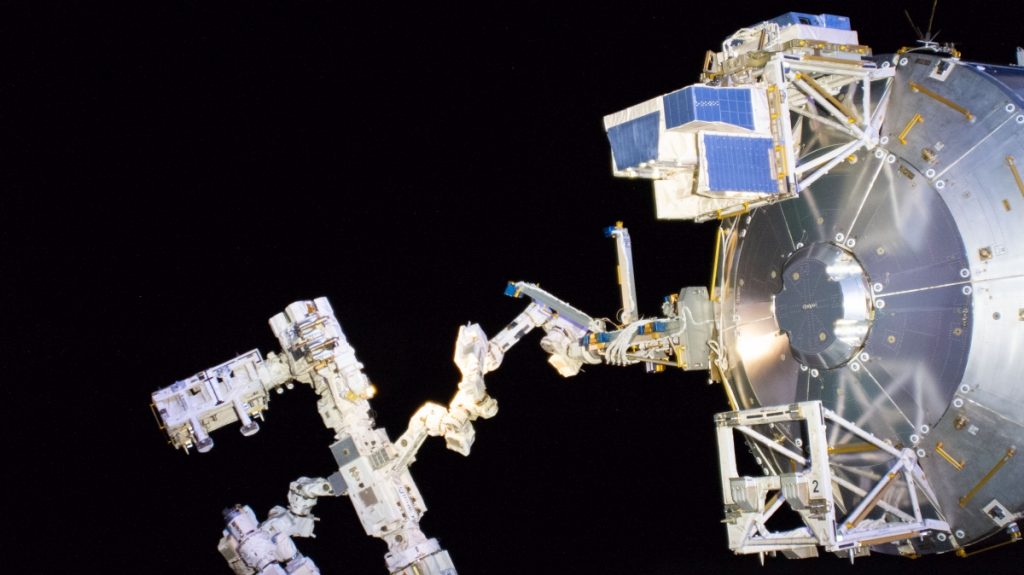

Euro Material Ageing

Arceon is officially amongst the selected companies of material scientists, experimenters and engineers to test materials for space applications on the Bartolomeo platform, the newest external platform to the International Space Station (ISS), participating in a pilot project of the European Space Agency (ESA) and the French space agency CNES. Arceon, in collaboration with DLR, will provide 4 different samples on the ISS to study the effect of Low Earth Orbit environment.